Chemical

Supplyline either directly or through our partners supply a number of OEM, Tier I / Tier II & Tier III suppliers and manufacturers.

Supplyline either directly or through our partners supply a number of OEM, Tier I / Tier II & Tier III suppliers and manufacturers.

These include companies like BASF / Du Pont & Ecolab.

We supply many more companies like these in this industry but due to the sensitive nature of these companies and our relationship with them we would only discuss these companies directly with serious end user enquiries which we would welcome. If you want to find out why so many Chemical companies trust and deal with Supplyline ID please get in touch.

LABEL TYPES FOR CHEMICALS FROM SUPPLYLINE ID

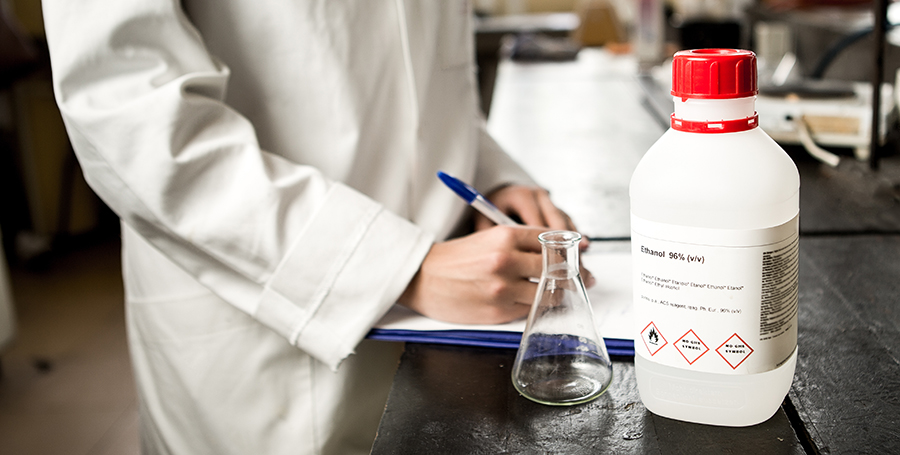

Chemical labels are required to withstand the toughest of demands within the chemical industry, and are subsequently designed to do so. All of our chemical labels are either Polypropylene or Polyethylene as they do not absorb water or oil, they also have a good resistance to prolonged UV exposure, extreme temperatures (hot and cold), abrasion, environmental factors and virtually all household chemicals. All our chemical labels are designed to last the lifetime of the packaging it is identifying, with data readability and adhesive strength that does not degrade over time.

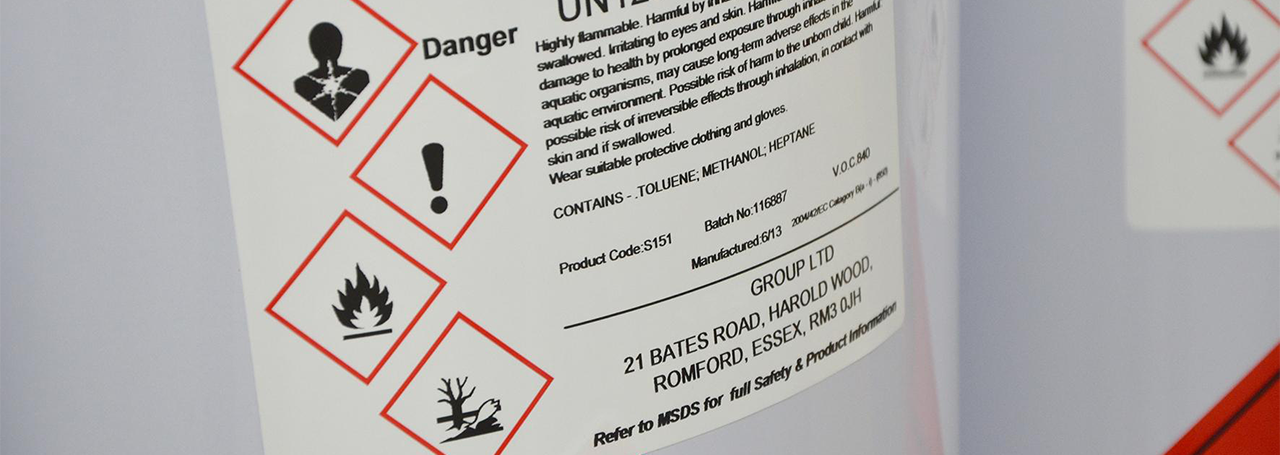

Reliable printing of GHS labels

Labels for bottles or drums containing chemicals communicate data and symbols required under GHS regulations (Globally Harmonized System of Classification and Labelling of Chemicals). Such information warns of the hazards to people and the environment during the transportation and utilisation of the product.

So it is critical for the label to be perfectly legible from the moment it is affixed until the residues are recycled and the container is cleaned.

Printing constraints on chemical product labelling

The printing of barcodes, product composition, product traceability data and GHS symbols must be resistant to external attack.

Products rubbing together, dripping solvent and demanding storage environments can all expose the ink to significant duress. Heat, cold, humidity, solvents, UV exposure: not all inks offer adequate resistance.

A label that complies with the GHS standard requires the printing of standardised red and black information and symbols.

The use of an ink/label combination certified to BS5609 (3 months immersion in sea water) provides guaranteed adhesive performance, print durability and abrasion resistance.

CLP Labelling

Once the hazardous properties of a substance or mixture have been identified, they need to be classified accordingly.

This is done by labelling the substance or mixture in accordance with CLP before placing it on the market, when:

- The substance or mixture is classified as hazardous.

- The mixture contains one or more substances classified as hazardous above a certain threshold.

- The article has explosive properties.

CLP defines the content of the label and the organisation of the various label elements. The label should be firmly attached to one or more of the packaging’s surfaces and has to include the following:

- The name, address and telephone number of the supplier

- The nominal quantity of a substance or mixture in packages made available to the general public (unless this quantity is specified elsewhere on the package)

- Product identifiers

- Where applicable, hazard pictograms, signal words, hazard statements, precautionary statements and supplemental information required by other legislation.

CLP sets general requirements for labelling to ensure the safe use and supply of hazardous substances and mixtures. Certain labelling exemptions apply e.g. to substances and mixtures contained in packaging that is small (typically less than 125 ml) or is otherwise difficult to label. Other examples are listed in Section 1.3 of Annex I to the CLP Regulation. The exemptions allow the supplier to omit the hazard and/or precautionary statements or the pictograms from the label elements normally required under CLP.

Asset Labels

Our asset labels are available in all shapes and sizes for different uses, Supplyline can manufacture asset labels in synthetic materials varying in thickness for rigidity, even metalized in some cases for extreme durability against abrasion, heat and tearing.

Hazard Labels

Labels we produce ourselves and supply via third party manufactures are full GHS compliant and will make sure your business is up to the required standard of safety.

Instruction Labels

Labels can be printed up to 8 colour with instructions or a usage-guide in a weatherproof material that should apply to any material, rough or smooth and withstand a number of environmental factors without peeling off.

Water/Oil Resistant Labels

Labels that are required to have an oil resistance tend to be made of a synthetic material that naturally repels water and oil, we can send you a few different samples of material/adhesives to see what works for you. Supplyline can also recommend a varnished paper label for a more cost effective solution to a short term labelling. Both of these label types adhere well to nearly all surfaces, including glass, metal, plastic, painted surfaces, polycarbonate and more.

Request a call back

| LABEL TYPES & MATERIALS WE USE | ||

| 3M Polyester | Ink Jet Receptacle | Recyclable Labels |

| A4 Laser Labels | Jet Gloss 90 | Sheet Labels |

| Anodised Aluminium | Laser Labels | Sprocket Fed |

| Blockout/Blackout | Loop Tags | Tags |

| Clear laminates | Metallised Silver/Polyester | Tamper Evident |

| Clear PE | Oven Proof | Tactile |

| Clear PP | Paper Direct Thermal (Eco or Topcoat) | Tickets |

| Domed | Paper Thermal Transfer (Matt Vellum or Gloss) | Vinyl |

| Dot Matrix Labels | Polyester (PET) | Void |

| Fabric & Woven Labels | Polyethylene (PE) | Ultra Destruct |

| Fan Fold Labels | Polypropylene (PP) | Window Stickers |

| Fan Fold Tags & Tickets | PVC | |

| Garden Centre Tags | Peel & Reveal | |

| ADHESIVES WE USE | ||

| Acrylic based | High Tack | Ultra High Tack |

| Blockout / Blackout | Peelable | Ultra Low Tack |

| Chilled | Permanent | Void |

| Fastyre | Rubber Based | Water Resistant |

| Freezer | Tamper Evident | |

| LABEL RESISTANCE SUPPLYLINE CAN OFFER | ||

| Chemicals | Handling | Scuff Proof |

| Extreme High Temperature | Moisture | Sea & Salt Water (BS5609 Standard) |

| Extreme Low | Outdoor Exposure | Solvents |

| Grease | Scratch Proof | UV Exposure |

| PRINTER & CODING RIBBONS SUPPLYLINE CAN OFFER | |

| Coding Ribbons Colours | Full/Resin Ribbons |

| Coding Ribbons Full/Resin | Hot Foil Ribbons |

| Coding Ribbons Wax/Resin | Near Edge Wax/Resins Ribbons |

| Cold Stamping Ribbons | Near Edge Full/Resins Ribbons |

| Colour Ribbons (Primary & Metallic) | Premium Wax Ribbons |

| Chemical Ribbons (chemical resistant) | Standard Wax Ribbons |

| Enhanced Wax Ribbons | Washable Ribbons (Textile / Clothing Printing |

| Our ribbons can meet the following certifications : | ||

| Food Contact Europe | RoHS | Halogens |

| Heavy Metals | Marine shipping (BS5609) | California Proposition 65 |

| REACH/SVHC | Food Contact USA | Print durability (UL) |

| Drug Master File | ||

![]()