Electronics

Supplyline only offer the highest quality ribbons from the market leading manufacturers that include Armor, ITW Thermal Films, Inkanto, Richoh & Sony plus all the genuine branded ribbons from Zebra, Honeywell and Toshiba. This enables us to meet any ribbon requirement with the perfect grade or ribbon type ensuring not only perfect print every time but also the correct resistance or protection to last the life of the product or application.

Supplyline only offer the highest quality ribbons from the market leading manufacturers that include Armor, ITW Thermal Films, Inkanto, Richoh & Sony plus all the genuine branded ribbons from Zebra, Honeywell and Toshiba. This enables us to meet any ribbon requirement with the perfect grade or ribbon type ensuring not only perfect print every time but also the correct resistance or protection to last the life of the product or application.

Buy Printer & Coding Ribbons from Supplyline, one of the largest resellers of Printer & Coding Ribbons in the Industry, we sell at the most competitive price and carry by far the largest stock range in the UK.

Challenge us to save you money, improve your print quality and increase the life of your printer or printhead, we wont be beaten on price.

RIBBON TYPES & APPLICATIONS FOR THE ELCETRONICS INDUSTRY

AXR 600W White ribbon to print highly durable electronics labels

Print battery labels with a 100% Halogen free and solvent resistant solution

One of the biggest Chinese electronics label printing company (batteries, laptop, etc.) has been challenged to print tiny white characters on plain black labels. they were looking for a better solution as they tried a ribbon that didn’t totally meet their requirement in terms of chemical composition- in particular Halogens -.

This giant manufacturer has pointed out the characteristics they were looking for:

- A product that is 100% Halogen free

- Resistant to solvents

- With good printing results and stable quality.

AXR 600W ribbon meets all these expectations:

- A great print sharpness to guarantee a nice print finishing and perfect readability of logos, barcodes, and small characters.

- Good resistance to solvents which are used during and after the manufacturing process

- ability to print at high speed in order to adapt to the production pace

- Excellent print quality on a wide range of printer settings and on both labels and flexible packaging

- High ink opacity to offer a great white print regardless the label colour

- Compatibility with the high throughputs of many industries

- The ink must comply with stringent electronics regulations on Halogens or Heavy metals (2011/65/EC)

AXR 600W is a great fit for all durable colored labels. It has now been running on this application with success for more than 2 years.

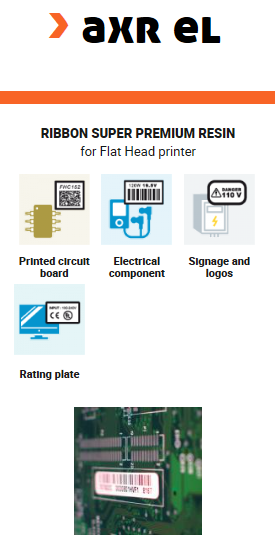

Printed circuit board identification and traceability

The label on a printed circuit board is subjected to significant stress throughout the production process. Poor quality or damaged printing can have an impact on production process monitoring, on logistics and on the use of the printed circuit board in the end product.

Such message legibility and durability requirements are at the heart of the process of selecting a print solution.

Printed circuit board label printing

The technologies used in component soldering and residue cleaning are very demanding: for example, temperatures can reach as high as 300°C (572°F) and the dispersal of solvents under high pressure may easily compromise the label and printed message.

Laboratory ageing tests for demanding sectors (e.g. aeronautics, automotive and armaments) reproduce the high mechanical and thermal stress to which the printed label is subjected (resistance to UV, humidity, heat, cold, temperature variation, etc.).

Certain international print performance regulations (UL standard) and those covering the use of regulated substances must also form part of the process for selecting the print technology.

inkanto ribbons for the printing of printed circuit board labels

Thermal Transfer technology is the most reliable print technology for printing unitary information on printed circuit board labels.

The high definition of the print head produces extremely accurate printing of all types of barcodes (vertical, horizontal, datamatrix, 2D, etc), alphanumerical characters and logos, even on very small labels.

inkanto Resin inks (AXR® family) in combination with synthetic labels (polyester, polyamide, polypropylene or polyimide) offer the best solution in terms of print quality and resistance to temperature, abrasion and solvents.

Within the range of inkanto Thermal Transfer ribbons there are solutions for complying with EU Directives 2011/65/EC (RoHS) and 2002/96/EC (WEEE), as well as meeting the restrictions of halogen compounds and the UL standard on printed label durability.

Labels subjected to testing conditions

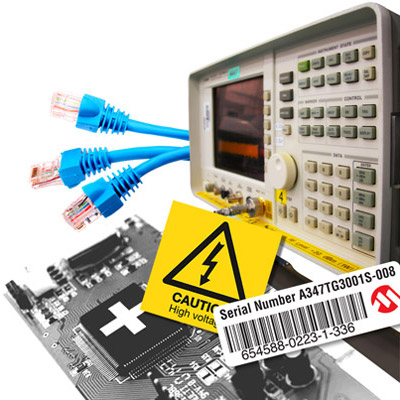

Whether it’s a computer hard disk, a laptop charger or a transformer for an electrical device, the identification of these components ensures traceability throughout the various stages of manufacturing, repair and recycling.

With Thermal Transfer technology, each component can be individually labelled with a barcode, serial number, user warnings, symbols and logos, even on a pre-printed medium.

Certain application environments are especially aggressive for printed material and may compromise the legibility of the information: abrasion, scratching, dust, heat, exposure to UV, etc. Thermal Transfer technology offers a combination of print media and ink able to handle the demands of each particular application environment.

inkanto ribbons for electrical components and accessories

inkanto Resin ribbons (AXR range) are the best suited to meet the demands of print quality and durability. They offer very high compatibility with synthetic labels (such as polyester, polyamide and polypropylene), which are generally used to label electrical components and accessories. The density of the black inks also enables the white label to be covered in such a way that the information stands out as a negative.

For printing on black labels, inkanto offers a range of white, metallic, silver and gold inks.

Within the range of inkanto Thermal Transfer ribbons there are solutions for complying with EU Directives 2011/65/EC (RoHS) and 2002/96/EC (WEEE), as well as meeting the restrictions of halogen compounds and the UL standard on printed label durability.

Resistant to soldering and cleaning solvents

- Print fineness suitable for small characters and barcodes

- Inks without halogenated substances

Electronics From ITW

Thermal transfer ribbons used in electronics applications need to be durable enough to withstand numerous manufacturing processes, high temperature extremes, soldering, chemicals, as well as shipping and assembly environments. Typical electronics applications where thermal transfer ribbons are used include: computers, printers, circuit boards, audio/video equipment and components, cell phones and other electronic mobile devices, toys and many other types of equipment that require a ribbon/label combination to support anti-static labeling requirements while delivering consistent print quality and performance. Generally resin thermal transfer ribbons meet these labeling requirements.

ITW Thermal Films Extreme Solutions™ can help you find the PrintheadSaver® thermal transfer ribbon that will match to your electronic label application for ultimate print durability.

PrintheadSaver® ribbons for electronics applications include:

- Extreme Series Midrange™ (ESM™) Ribbons

- Extreme Series Resin™ (ESR™) Ribbons

Request a call back

| Our ribbons can meet the following certifications : | ||

| Food Contact Europe | RoHS | Halogens |

| Heavy Metals | Marine shipping (BS5609) | California Proposition 65 |

| REACH/SVHC | Food Contact USA | Print durability (UL) |

| Drug Master File | ||

![]()

| LABEL TYPES & MATERIALS WE USE | ||

| 3M Polyester | Ink Jet Receptacle | Recyclable Labels |

| A4 Laser Labels | Jet Gloss 90 | Sheet Labels |

| Anodised Aluminium | Laser Labels | Sprocket Fed |

| Blockout/Blackout | Loop Tags | Tags |

| Clear laminates | Metallised Silver/Polyester | Tamper Evident |

| Clear PE | Oven Proof | Tactile |

| Clear PP | Paper Direct Thermal (Eco or Topcoat) | Tickets |

| Domed | Paper Thermal Transfer (Matt Vellum or Gloss) | Vinyl |

| Dot Matrix Labels | Polyester (PET) | Void |

| Fabric & Woven Labels | Polyethylene (PE) | Ultra Destruct |

| Fan Fold Labels | Polypropylene (PP) | Window Stickers |

| Fan Fold Tags & Tickets | PVC | |

| Garden Centre Tags | Peel & Reveal | |

| ADHESIVES WE USE | ||

| Acrylic based | High Tack | Ultra High Tack |

| Blockout / Blackout | Peelable | Ultra Low Tack |

| Chilled | Permanent | Void |

| Fastyre | Rubber Based | Water Resistant |

| Freezer | Tamper Evident | |

| LABEL RESISTANCE SUPPLYLINE CAN OFFER | ||

| Chemicals | Handling | Scuff Proof |

| Extreme High Temperature | Moisture | Sea & Salt Water (BS5609 Standard) |

| Extreme Low | Outdoor Exposure | Solvents |

| Grease | Scratch Proof | UV Exposure |

| PRINTER & CODING RIBBONS SUPPLYLINE CAN OFFER | |

| Coding Ribbons Colours | Full/Resin Ribbons |

| Coding Ribbons Full/Resin | Hot Foil Ribbons |

| Coding Ribbons Wax/Resin | Near Edge Wax/Resins Ribbons |

| Cold Stamping Ribbons | Near Edge Full/Resins Ribbons |

| Colour Ribbons (Primary & Metallic) | Premium Wax Ribbons |

| Chemical Ribbons (chemical resistant) | Standard Wax Ribbons |

| Enhanced Wax Ribbons | Washable Ribbons (Textile / Clothing Printing |