Healthcare

Supplyline only offer the highest quality ribbons from the market leading manufacturers that include Armor, ITW Thermal Films, Inkanto, Richoh & Sony plus all the genuine branded ribbons from Zebra, Honeywell and Toshiba. This enables us to meet any ribbon requirement with the perfect grade or ribbon type ensuring not only perfect print every time but also the correct resistance or protection to last the life of the product or application.

Supplyline only offer the highest quality ribbons from the market leading manufacturers that include Armor, ITW Thermal Films, Inkanto, Richoh & Sony plus all the genuine branded ribbons from Zebra, Honeywell and Toshiba. This enables us to meet any ribbon requirement with the perfect grade or ribbon type ensuring not only perfect print every time but also the correct resistance or protection to last the life of the product or application.

To discuss your application or enquiry, please contact us via telephone, email or by filling out the ribbon form.

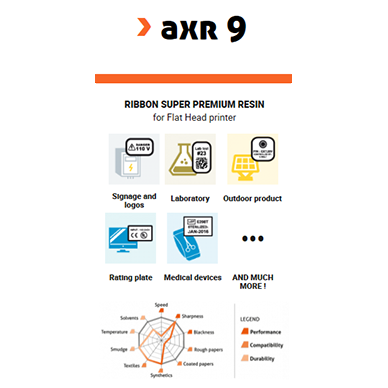

RIBBON TYPES & APPLICATIONS FOR HEALTHCARE

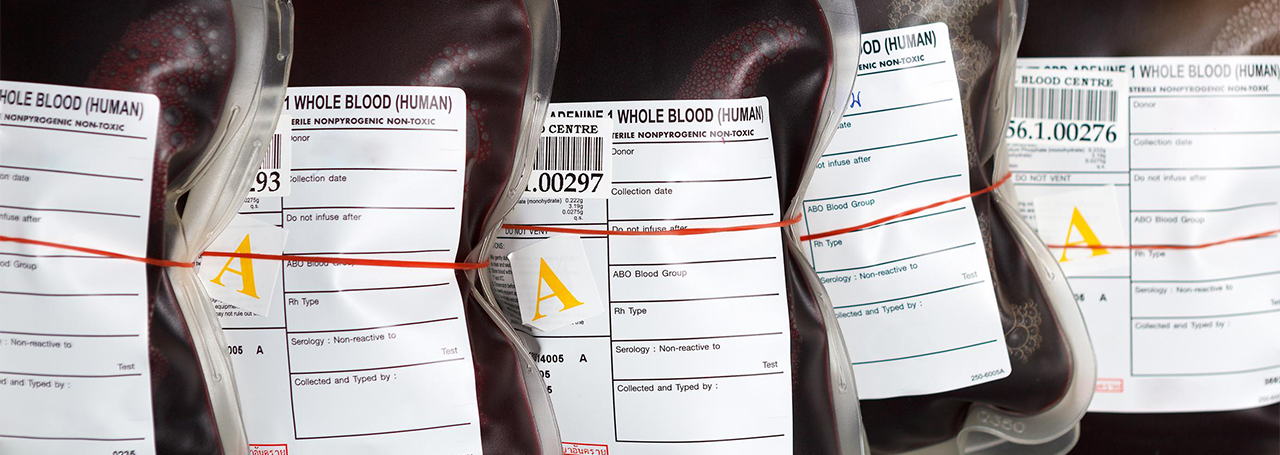

25 Million blood bags marked with Armor AXR9 ribbon

Guaranteeing the legibility of traceability data in demanding environments.

This global giant supplies hospitals and blood donation centres with complete blood management solutions (devices, software, consultancy). For this sensitive activity subject to strict regulations, the head office of Haemonetics located in Braintree, Massachusetts, selects the best offers on the market to create the solutions it offers to its customers worldwide.

It has therefore selected the inkanto Thermal Transfer resin film AXR®9 to equip the Zebra PAX4 print-and-apply printers on the production lines for plasma bottles located in a controlled environment.

The particular demands of this production process and, more specifically, packaging process, are such that the specifications setting out the required levels of resistance from the print solution incorporates the following constraints:

- Gamma sterilisation process

- Storage at a temperature of -50C° over 6 months

- Thawing through condensation

- High pressure shower at a temperature of +70C°

- Certified non-toxic

- Abrasion during transportation

During test phases, the manufacturer was able to validate the non-toxicity of the ink followed by real-life test conditions: freezing, thawing, humidification, ageing, and resistance to the adhesive ribbon, all of which were fully satisfactory.

The excellent application properties combined with the flexibility offered by Thermal Transfer technology in terms of the printing of variable data, not to mention the savings to be made by using white labels rather than pre-printed labels, were the factors behind the approval of the solution.

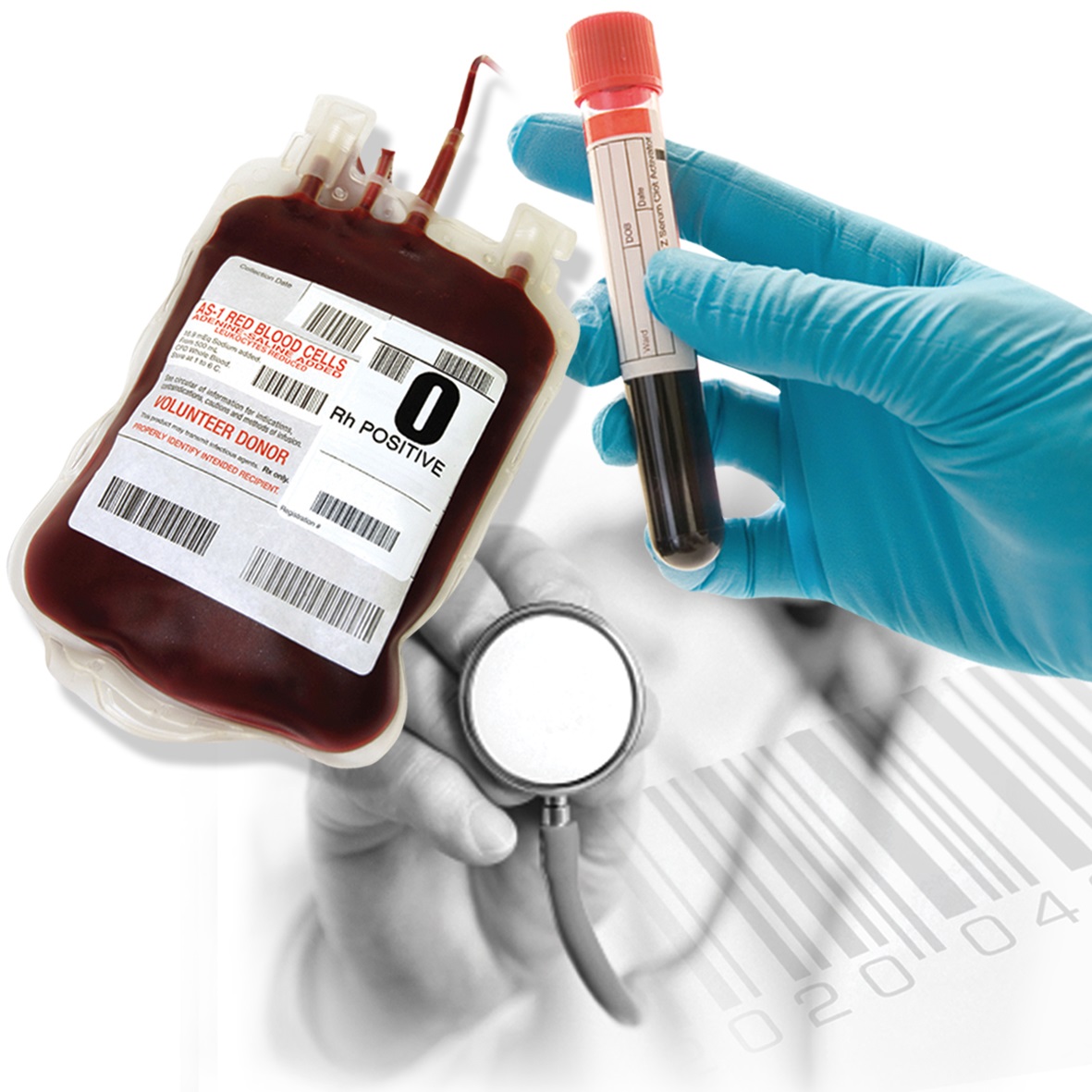

Data security guarantees patient safety

Collecting blood is a simple process, but ensuring the identification and traceability of each and every bag up to the receiving patient is a very demanding challenge. Blood bag labels contain essential information such as the name and contact details of the producer and all of the donor’s identification details: blood group, conservation period, barcodes, laboratory tests, etc.

Just some of the sensitive information required to be protected by a print of high quality and high resistance. The various blood treatment processes (such as centrifugation), the sterilization by autoclave (100 to 140°C / 212 to 284°F) and the various stages of storage (up to -50°C/-58°F) and transport subject the ink to high levels of stress.

A damaged barcode or blood group would make the blood bag unusable.

inkanto ribbons for marking blood bags

In order that the printing on the label remains intact throughout the lifecycle of the blood bag, it is recommended to use the resin-based inks from the AXR® range which combine:

- excellent print finish, even for small barcodes such as Datamatrix or 2D,

- resistance to the cold, to the steam of the autoclave and to abrasions,

- ability to print on all of the label materials generally used on blood bags (coated paper and synthetic materials).

It is also possible to print primary production data directly onto the bag by using the black or coloured ribbons for near-edge printers.

The registration of inkanto inks with the FDA in the USA enables users to easily compile their Drug Master File.

Whether in the chemicals, food processing or pharmaceuticals industry, certain laboratory environments are aggressive for printed labels, to the point of their becoming unusable in terms of the identification and traceability of products and samples.

Customised printing

With its ability to print single labels, Thermal Transfer printing offers the flexibility required for the marking of all kinds of identification and traceability data on products used in the laboratory.

Thermal Transfer ribbons offer very precise printing of barcodes and identification data on even the smallest of labels which are frequently used for test tubes, microscope slides and flasks.

The wide variety of available Thermal Transfer inks enables each laboratory to find a tailor-made solution in terms of print quality and durability.

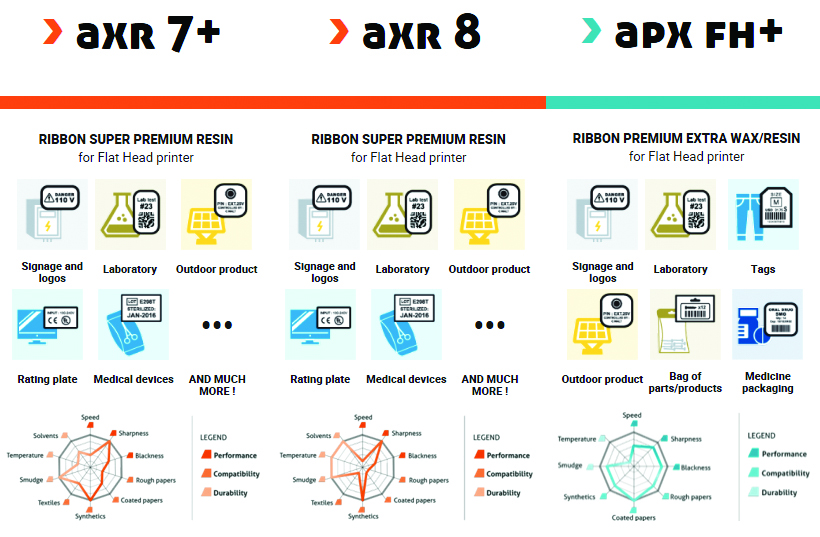

inkanto ribbons for laboratory labels

inkanto Wax-Resin inks (APR®/APX® range) offer great print flexibility for the marking of small characters and of horizontal, vertical, 2D and DataMatrix barcodes. The APR® ribbons offer high levels of performance on both paper and plastic (synthetic) labels and are perfectly suited for products subject to repeated handling but not exposed to chemical substances.

A Resin ink (AXR® range) is the best suited for extreme applications. In combination with synthetic labels they offer the optimum mix of quality and durability. The AXR® ribbons meet the resistance needs of products with a long life cycle, which are subject to repeated handling, are stored or sterilised at extreme temperatures or are in contact with chemical substances.

inkanto ribbons comply with regulations on heavy metals (RoHS), do not contain any substances of very high concern (REACH), enable users to comply with European (1935/2004/EC) and US (FDA) food contact regulations and are ideal for printing red and black GHS labels.

Ideal for the individual traceability of each bag

- Resistant to the various sterilisation techniques

- Inks with a Drug Master File number

Sensitive information in aggressive environments

Throughout the lifespan of the product, identification and traceability data is subject to various forms of attack able to affect the legibility of the information:

- Certain sterilization processes such as autoclave subject the inks to a stern test, combining humidity with high temperatures. These conditions favour information becoming erased during contact with other products or during handling.

- In the hospital environment, the use of alcohol solutions during patient care may degrade the printed matter on medical device labels during handling.

- No heavy metals (2002/95/EC)

- Suitable for food contact: Europe (1935/2004) and USA (FDA)

- No Biphenol A or S

- No SVHCs (REACH)

- Extreme Series Midrange™ (ESM™) Wax/Resin Ribbons

- Extreme Series Resin™ (ESR™) Ribbons

Complying with labelling regulations

In the USA for example, the UDI (Unique Device Identification) system requires a unique traceability code, a barcode and a representation of the product on the label for every medical device.

Thermal Transfer enables unitary printing of labels with all types of barcodes, logos, product drawings and other small characters: a guaranteed flexibility for medical device manufacturers.

Medical device manufacturers wishing to sell their products in the USA must submit a Drug Master File to the FDA to validate the safety of all of the product’s components, including printing inks. ARMOR supports users in this area by making ink composition information available to the FDA.

inkanto ribbons for medical devices

inkanto’s resin-based AXR® range offers the best combination of print quality and resistance.

inkanto’s inks comply with some of the most demanding regulations in terms of human health:

Resin-based inks from the AXR® range are compatible with labels made of coated papers, synthetics and textiles, including specialist materials used in sterilization such as Tyvek®.

Healthcare Ribbons from ITW

Bar code labels used in healthcare applications need to be reliable, durable and remain scanable. These thermal transfer ribbons need to be durable enough to withstand a number of conditions including autoclave resistance, solvents found in clean rooms and within the manufacturing process while maintaining legible print. Thermal transfer ribbons used in the healthcare environment contain critical information needed to assure proper and accurate identification of medication, blood bags, medical devices, and patient identification to improve safety and traceability in the healthcare environment. In addition, these bar code ribbons often need to meet a number of FDA guidelines and/or have specific certificate of compliances to meet the demanding performance characteristics required in this market sector where patient well being is critical.

ITW Thermal Films Extreme Solutions™ can help you find the PrintheadSaver® thermal transfer ribbon that is designed for your healthcare label application.

PrintheadSaver® ribbons for healthcare applications include:

Request a call back

| Our ribbons can meet the following certifications : | ||

| Food Contact Europe | RoHS | Halogens |

| Heavy Metals | Marine shipping (BS5609) | California Proposition 65 |

| REACH/SVHC | Food Contact USA | Print durability (UL) |

| Drug Master File | ||

![]()

| LABEL TYPES & MATERIALS WE USE | ||

| 3M Polyester | Ink Jet Receptacle | Recyclable Labels |

| A4 Laser Labels | Jet Gloss 90 | Sheet Labels |

| Anodised Aluminium | Laser Labels | Sprocket Fed |

| Blockout/Blackout | Loop Tags | Tags |

| Clear laminates | Metallised Silver/Polyester | Tamper Evident |

| Clear PE | Oven Proof | Tactile |

| Clear PP | Paper Direct Thermal (Eco or Topcoat) | Tickets |

| Domed | Paper Thermal Transfer (Matt Vellum or Gloss) | Vinyl |

| Dot Matrix Labels | Polyester (PET) | Void |

| Fabric & Woven Labels | Polyethylene (PE) | Ultra Destruct |

| Fan Fold Labels | Polypropylene (PP) | Window Stickers |

| Fan Fold Tags & Tickets | PVC | |

| Garden Centre Tags | Peel & Reveal | |

| ADHESIVES WE USE | ||

| Acrylic based | High Tack | Ultra High Tack |

| Blockout / Blackout | Peelable | Ultra Low Tack |

| Chilled | Permanent | Void |

| Fastyre | Rubber Based | Water Resistant |

| Freezer | Tamper Evident | |

| LABEL RESISTANCE SUPPLYLINE CAN OFFER | ||

| Chemicals | Handling | Scuff Proof |

| Extreme High Temperature | Moisture | Sea & Salt Water (BS5609 Standard) |

| Extreme Low | Outdoor Exposure | Solvents |

| Grease | Scratch Proof | UV Exposure |

| PRINTER & CODING RIBBONS SUPPLYLINE CAN OFFER | |

| Coding Ribbons Colours | Full/Resin Ribbons |

| Coding Ribbons Full/Resin | Hot Foil Ribbons |

| Coding Ribbons Wax/Resin | Near Edge Wax/Resins Ribbons |

| Cold Stamping Ribbons | Near Edge Full/Resins Ribbons |

| Colour Ribbons (Primary & Metallic) | Premium Wax Ribbons |

| Chemical Ribbons (chemical resistant) | Standard Wax Ribbons |

| Enhanced Wax Ribbons | Washable Ribbons (Textile / Clothing Printing |