Tyre

LABEL TYPES FOR THE TYRE INDUSTRY FROM SUPPLYLINE ID

Tyre labels are an integral part of the regulation bought in by the EU in 2012 to make sure as much information as possible to offered to the consumer. They are a minimum requirement for any tyre manufacturer or distributor.

Tyre labels are an integral part of the regulation bought in by the EU in 2012 to make sure as much information as possible to offered to the consumer. They are a minimum requirement for any tyre manufacturer or distributor.

In August 2018, the EU made an announcement in regards to their plan to update and improve current regulations by making it a requirement for any retailers to show the labels to motorists when tyres are purchased.

In August 2018, the EU made an announcement in regards to their plan to update and improve current regulations by making it a requirement for any retailers to show the labels to motorists when tyres are purchased.

It is expected that the new regulations will also require labels to include the tyres’ snow and ice performance, as well as ratings for mileage and wear.

Supplyline offers a range of suitable label substrates and adhesives that would suit this application. None however would we recommend more than Avery Fastyre, a product specially designed to meet the performance requirements of automotive tyre labelling.

With a high-tack rubber based adhesive designed for use on rough and difficult surfaces such as tyre rubber. The product will remain free of staining pattern from the tyre tread under the majority of normal storage conditions

Tyre vulcanisation and distribution labels

There are two types of tyre label :

- Tyre vulcanisation labels: these barcode labels provide product traceability during manufacture. The application of pressure on the label at the same time as exposure to high temperature (200°C) can damage the printed message.

- Tyre distribution labels: contains identification information for the user (brand, model and dimensions). It must be perfectly legible at the point of sale and be able to resist the various forms of attack during transportation and storage.

Fastyre

Fastyre has been specially formulated for use on rubber tyres and other surfaces that standard labels might struggle to adhere to.

Commonly used in the automotive sector as they can be printed with information such as barcodes, product details and even EU rating info.

However their extreme durability and adhesive also make them very popular in the construction industry where materials are stored outside.

Other interesting uses for Fastyre labels are on fire extinguishers and chemical drums, plus they’re even capable of being used on raw wood!

Tyre label printing constraints

Tyre labels are subjected to significant duress throughout the various production and logistics stages: vulcanisation, abrasion, rain, cold, long-duration storage, UV light… all constitute forms of attack likely to damage the printed matter. One illegible barcode and the entire logistics chain may be disrupted.

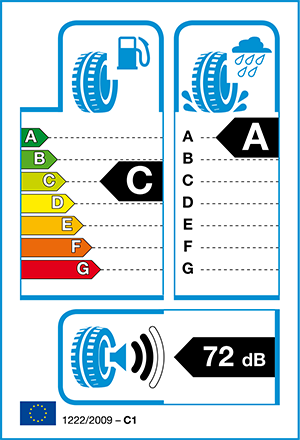

In accordance with the new European standard 1222/2009 on tyre labelling, manufacturers and importers in the European Union must provide the end user with tyre performance data in terms of rolling resistance, wet braking distances and noise emissions.

Tyre labels, frequently pre-printed, require customised technical data for each product: dimensions, symbols, barcodes, etc.

ARMOR ribbons for tyre label printing

Thermal Transfer technology can be used to print both vulcanisation labels and tyre distribution labels.

For tyre distribution labels printed on coated or synthetic paper, ARMOR Wax-Resin inks offer an excellent compromise between resistance and cost. For more aggressive environments, Resin inks offer improved print durability.

For synthetic vulcanisation labels, it is recommended to print using ARMOR Resin inks for optimum levels of resistance to heat and solvents.

Resistant to high-temperature vulcanisation processes

- Print fineness suitable for small characters and barcodes

Request a call back

| LABEL TYPES & MATERIALS WE USE | ||

| 3M Polyester | Ink Jet Receptacle | Recyclable Labels |

| A4 Laser Labels | Jet Gloss 90 | Sheet Labels |

| Anodised Aluminium | Laser Labels | Sprocket Fed |

| Blockout/Blackout | Loop Tags | Tags |

| Clear laminates | Metallised Silver/Polyester | Tamper Evident |

| Clear PE | Oven Proof | Tactile |

| Clear PP | Paper Direct Thermal (Eco or Topcoat) | Tickets |

| Domed | Paper Thermal Transfer (Matt Vellum or Gloss) | Vinyl |

| Dot Matrix Labels | Polyester (PET) | Void |

| Fabric & Woven Labels | Polyethylene (PE) | Ultra Destruct |

| Fan Fold Labels | Polypropylene (PP) | Window Stickers |

| Fan Fold Tags & Tickets | PVC | |

| Garden Centre Tags | Peel & Reveal | |

| ADHESIVES WE USE | ||

| Acrylic based | High Tack | Ultra High Tack |

| Blockout / Blackout | Peelable | Ultra Low Tack |

| Chilled | Permanent | Void |

| Fastyre | Rubber Based | Water Resistant |

| Freezer | Tamper Evident | |

| LABEL RESISTANCE SUPPLYLINE CAN OFFER | ||

| Chemicals | Handling | Scuff Proof |

| Extreme High Temperature | Moisture | Sea & Salt Water (BS5609 Standard) |

| Extreme Low | Outdoor Exposure | Solvents |

| Grease | Scratch Proof | UV Exposure |

| PRINTER & CODING RIBBONS SUPPLYLINE CAN OFFER | |

| Coding Ribbons Colours | Full/Resin Ribbons |

| Coding Ribbons Full/Resin | Hot Foil Ribbons |

| Coding Ribbons Wax/Resin | Near Edge Wax/Resins Ribbons |

| Cold Stamping Ribbons | Near Edge Full/Resins Ribbons |

| Colour Ribbons (Primary & Metallic) | Premium Wax Ribbons |

| Chemical Ribbons (chemical resistant) | Standard Wax Ribbons |

| Enhanced Wax Ribbons | Washable Ribbons (Textile / Clothing Printing |

| Our ribbons can meet the following certifications : | ||

| Food Contact Europe | RoHS | Halogens |

| Heavy Metals | Marine shipping (BS5609) | California Proposition 65 |

| REACH/SVHC | Food Contact USA | Print durability (UL) |

| Drug Master File | ||

![]()